Inspection of particle boards

Time-to-market and high product quality standards are pushing the use of automatic visual inspection systems for defect detection in a wide broad of applications. The defect detection of particle boards requires the identification of all the printed and natural wood defects that can occur. The availability of information about the particle board to inspect (e.g. the pattern used to print the surface of the board) could increase heavily the defect detection capability of a quality assessment system. Nevertheless, most of the times the pattern is not available during the defect detection phase (i.e. when the pattern changes quickly or when printing and defect detection are not performed by the same company).

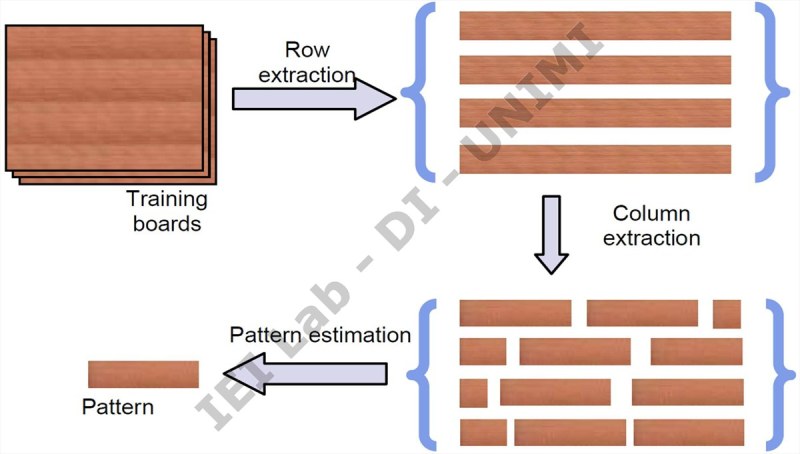

We have researched innovative defect detection approaches capable to automatically extract the repetitive patterns that are generally present in the printed-matters. The extracted patterns are then used in the proper defect detection phase that can thus achieve high defect detection performances. Real wood patterns prove that the studied defect detection systems achieves very high classification capability.

Schema of the studied approach for the inspection of particle boards

References

-

M. Gamassi, V. Piuri, F. Scotti,

M. Roveri, "Genetic techniques for pattern extraction in particle boards images", in Proc. of the 2006 IEEE Int. Conf. on Computational Intelligence for Measurement Systems and Applications (CIMSA 2006), La Coruna, Spain, pp. 129-134, July 10-12, 2006. ISBN: 1-4244-0244-1. [DOI: 10.1109/CIMSA.2006.250761][PDF]

-

V. Piuri, M. Roveri, F. Scotti, "Visual inspection of particle boards for quality assessment", in Proc. of the 2005 IEEE Int. Conf. on Image Processing (ICIP 2005), Genoa, Italy, pp. 521-524, September 11-14, 2005. ISBN: 0-7803-9134-9. [DOI: 10.1109/ICIP.2005.1530443][PDF]